Assembling and Disassembling the “Center shaft” in the Spectra 20, 40, 60 and 100 models

Step 1 : The parts that go into assembling the central shaft are

a) Bottom Bush (Stainless Steel)

b) “O” Ring

c) Gun Metal bush

d) Oil Seal

e) Teflon Seal

f) Stainless steel center shaft

These parts are shown in the picture below.

Step 2 : The method of assembling is as follows

a) The Bottom bush is first glued on to the granite stone bottom with an epoxy glue and is permanently fixed at the factory.

b) Next the “O” ring is inserted into the Bottom bush. There will be two grooves within the gun metal bush. The narrower of the two accepts the "O" Ring. The wider of the two grooves is filled with white grease.

Gun Metal Bush showing the Grooves

Gun Metal Bush showing the Grooves

C) The Teflon Washer, the oil Seal and the Gun Metal bush are slipped over the SS Shaft as shown below.

d) Then, the gear sprocket wheel is bolted using the four bolts to the bottom of the stone. The four bolts are not fully tighted at this stage.

e) Then, the Stainless Steel Central shaft is inserted from the top (ie. from inside the drum), through the Stainless Steel bush, and then and using a wooden hammer, hammered down as far as it would go, and through the gear sprocket bearings. If you have access to a Hydraulic Press in a machine shop of suitable size, then it could be used instead of wooden hammering.

The final assembly would appear as shown in picture above.

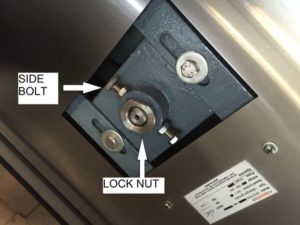

f) Finally, the entire assembly of the drum,stone and pulley is bolted down to the frame/chasis of the melangeur/grinder as below. The Lock NUT is first fully tightened, and then, the two side bolts are tightened.

Step 3 : To disassemble the central shaft, it is the reverse process.

a) Loosen the side bolts, and remove the Lock Nut.

b) With a wooden hammer, hit the central stainless steel shaft from bottom, such that the shaft moves up and eventually is removed from the unit.

Now, using a screwdriver or similar instrument, gently pry the Teflon seal, Oil Seal, Gun Metal bush and the ‘O’ ring out of the Bottom bush. In case of difficulty in prying out, you could nudge out the O Ring by pushing it out from the underside of the Bottom bush.